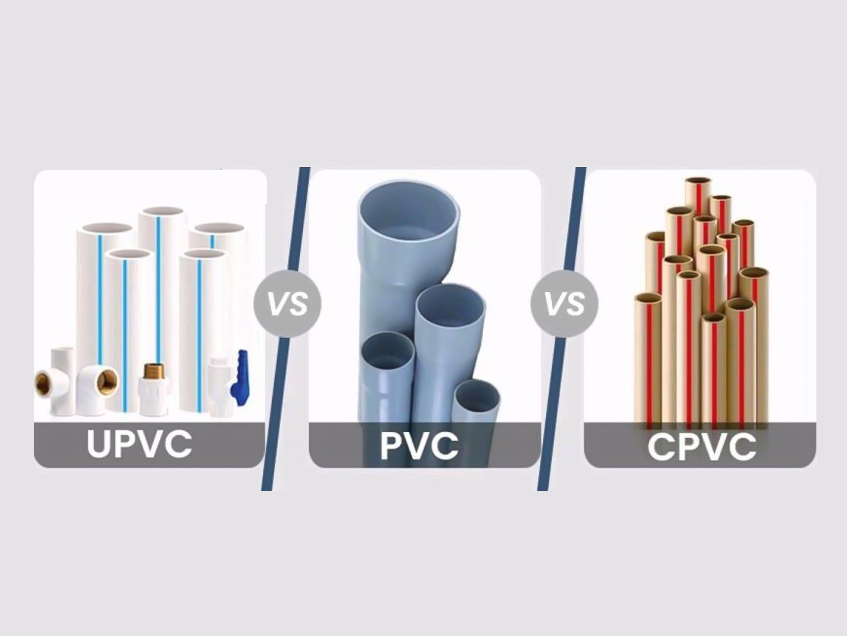

Plastic piping plays a crucial role in modern construction, plumbing, and industrial applications. Among the most commonly used materials are PVC (Rigid Polyvinyl Chloride)/ UPVC (Unplasticized PVC), and CPVC (Chlorinated PVC). As per ASTM standard, Rigid or unplasticized PVC is commonly abbreviated as PVC.

Choosing the right type of pipe is essential to ensure durability, safety, and efficiency in any project. This article explores the key differences, benefits, and applications of Rigid PVC/ UPVC, and CPVC pipes to help you make an informed decision.

Looking for high-quality plastic pipes for your project? Discover the wide range of solutions from Salem Balhamer Plastic today!

1. What Are PVC/UPVC, and CPVC?

Before comparing their differences, it is important to understand what each type of pipe is:

- PVC (Rigid Polyvinyl Chloride)/ uPVC (Unplasticized PVC) : As per ASTM standard Rigid PVC is commonly abbreviated as PVC. This is a rigid, unplasticized version of PVC that is stronger, more durable, and chemical-resistant. A widely used thermoplastic material known for its affordability, versatility, and resistance to corrosion. It is commonly found in plumbing, drainage, and irrigation systems.

- CPVC (Chlorinated PVC): A modified form of PVC that undergoes chlorination to enhance its temperature and chemical resistance, making it ideal for hot water systems and industrial applications.

2. Key Differences Between PVC/UPVC, and CPVC

As per ASTM standard Rigid PVC is commonly abbreviated as PVC. This is a rigid, unplasticized version of PVC.

| Feature | Rigid PVC/UPVC | CPVC | |

| Material Composition | No plasticizers | Chlorinated for extra durability | |

| Flexibility & Strength | More Rigid | Stronger | |

| Temperature Resistance | Up to 60°C | Up to 93°C | |

| Chemical & Corrosion Resistance | Excellent | Superior | |

| Common Uses | Drainage, irrigation, low-pressure plumbing, Potable water, industrial piping, windows | Hot water, chemical transport, HVAC systems |

Key Takeaway: UPVC & PVC (Rigid PVC) are same as per ASTM standard. If higher temperature and chemical resistance are needed, CPVC is preferred.

3. Applications of PVC/UPVC, and CPVC Pipes

A. PVC/UPVC Applications

- Drainage and wastewater systems

- Irrigation and agricultural water distribution

- Electrical conduit protection

- Low-pressure plumbing systems

- Potable water supply lines (safe for drinking water)

- Industrial piping systems

- Window frames and door profiles

- Sewage and wastewater treatment plants

C. CPVC Applications

CPVC pipes are ideal for:

- Hot and cold water plumbing systems

- Chemical processing industries

- HVAC and fire sprinkler systems

- High-pressure industrial piping

4. Choosing the Right Type for Your Project

To select the most suitable pipe, consider the following factors:

- Temperature requirements – If your system handles hot water, choose CPVC.

- Pressure levels – For high-pressure applications, UPVC/PVC and CPVC are better options.

- Chemical exposure – If pipes are exposed to strong chemicals, CPVC provides superior resistance.

- Cost and budget – PVC/UPVC is the most affordable, while CPVC offer added benefits at a higher price.

Need expert guidance on selecting the right pipe? Contact Salem Balhamer Plastic today for customized solutions!

Conclusion

Understanding the differences between PVC/UPVC, and CPVC is essential for choosing the best material for your specific needs. Each type offers unique benefits:

- PVC/UPVC is cost-effective and great for drainage and irrigation, rigid, safe for potable water, and used in industrial applications.

- CPVC can withstand higher temperatures and chemicals, making it suitable for hot water and industrial uses.

Selecting the right type ensures longevity, efficiency, and safety in your plumbing or construction project.

Upgrade your plumbing system with the best-quality plastic pipes! Explore Salem Balhamer Plastic’s premium range of PVC/UPVC, and CPVC solutions today.